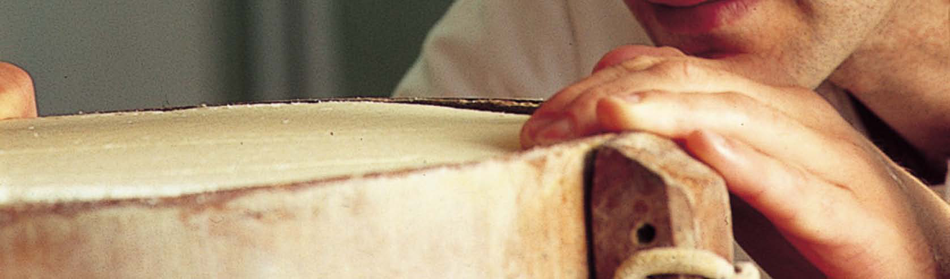

Today in the Latteria Sociale in Branzi, the cheesemakers still cut the curd with their expert hands: each piece must correspond to the right amount for one cheese. Opportunely hand-crafted and shaped, the dense mass is then placed in the traditional moulds and covered with a "pata" cloth from days gone by. Today in the Latteria Sociale in Branzi, the cheesemakers still cut the curd with their expert hands: each piece must correspond to the right amount for one cheese. Opportunely hand-crafted and shaped, the dense mass is then placed in the traditional moulds and covered with a "pata" cloth from days gone by.

The moulds serve to give its traditional round shape with a diameter of 40 or 45 cm and a height of 9 cm and a V-shaped side. The pata cloth holds the mass during pressing, the final phase when the curd is placed in the mould.

After a few dozen minutes in the press, the cheeses are removed then left in their moulds without the cloth, and then turned two or three times.

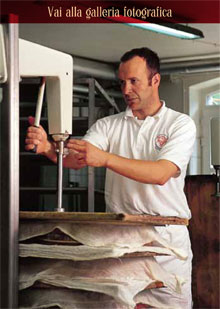

Salting is done by immersing the cheese in a brine bath. After three days, the cheeses are moved to the racks in the ageing storage areas. The ageing process is fundamental for the quality of Branzi cheese. The climate-controlled rooms at the Latteria and the local air ensure optimal conditions.

The forms are turned several times, brushed and rasped and treated to protect the rind. Periodic hammering allows expert ears to check the ageing and plugging phases, done on sample cheeses to directly verify the product's quality. |